Stainless Steel Coating – The HVAF And HVOF Thermal Spray Properties

High velocity thermal sprayed stainless steel coatings provide an inexpensive way to protect parts and equipment from an abrasive and corrosive environment.

Just 100 microns (0.004”) of a Kermetico HVAF or HVOF metal coating provides an impermeable barrier protecting the substrate from both abrasive and corrosive media.

WCCoCr or Cr3C2-NiCr hard metal coatings protect from erosion and abrasive wear better, but they are too expensive for many applications.

Stainless steel coatings provide a well-balanced approach to cost-effective corrosion protection in different environments.

The Corrosion Resistance Of Stainless Steel Coatings

Our HVOF and HVAF stainless steel coatings provide a way to create a barrier protecting steel components or structures against corrosion in seawater or corrosive solutions such as mineral or organic acids.

The comparatively low cost of the feedstock powder and the diverse range of chemical compositions of Fe-based materials provide a wide variety of coating choice for a corrosion engineer.

- Stainless steel 316 and 316L. Grade 316 contains molybdenum, which gives 316 good overall corrosion resistant properties, particularly high resistance to pitting and crevice corrosion in chloride environments. Grade 316L, the low carbon version of 316, is immune to grain boundary carbide precipitation. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures.

- High-hardness Hoganas 3.50 shows better corrosion resistance than 316 type alloys in H2S, H2SO4and seawater conditions.

- FeCrNi and FeCrAl thermal sprayed coatings have been successfully used in the applications where corrosion, wear and oxidation resistance at elevated temperatures are involved. Chromium oxidation results in protective oxide layer which hinders corrosion.

Through porosity of some other coatings carries the risk of penetration of liquid to the substrate making the noble metl coating subject to under-film corrosion. Also, porosity and inhomogeneity on the surface of the powder coating can make it prone to crevice corrosion. Our coatings are gas-tight.

The Corrosion Protection Performance Of Our HVOF And HVAF Stainless Steel Coatings Compared To Other Thermal Spray Technologies

Different spraying techniques need altering coating thickness to achieve the same result.

Why?

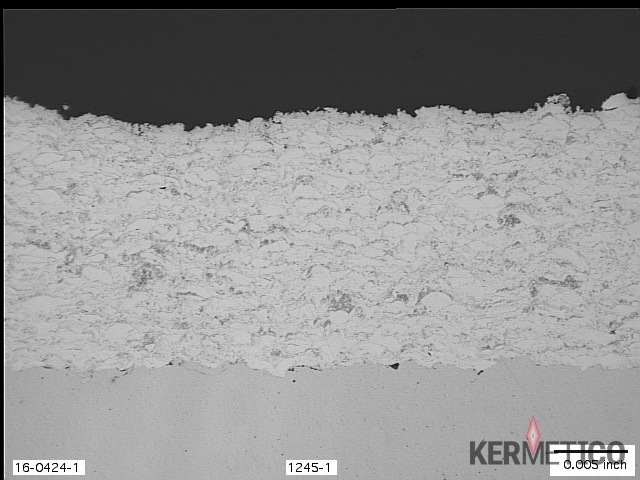

An iron-based thermal sprayed coating has a lamellar structure, and its properties are characterized by the nature and strength of the bonds between different particles.

High coating porosity and lower particle bond strength typically result from lower particle speed and higher process temperature along with higher oxygen content.

Flame spray (powder or wire), twin wire arc and air plasma produce very oxidized and porous coatings which result in the need for 500+ micron (0.020”) coatings for Fe-based materials to mitigate corrosion.

Conventional HVOF and Detonation processes provide substantially better results, but process temperature and oxygen content are still too high. Good HVOF Fe-based coatings prevent corrosion when they have at least 150 microns (0.006”) of thickness.

The Kermetico HVAF process is characterized by substantially lower temperatures (nearly 1,000 °C |1.800°F less than HVOF and Detonation) and higher particle velocities (over 1,000 m/sec | 3,300 ft./sec.).

Said process properties minimize particle oxidation and lead to high-bond, gas-tight stainless steel coatings at 100 microns (0.004”).

A 100 Microns Kermetico steel coating Provides Corrosion Protection As well As 150 Microns Of Conventional HVOF Coating.

Not a big deal?

Here is the best point:

Kermetico HVOF and HVAF equipment sprays five times faster and at a much lower cost than conventional HVOF systems.

In the same spray booth, with the same stainless spray powder, you can make the same coating job spraying:

- 150 microns coating five hours at $250 per hour with HVOF – total $1,250

- 100 microns coating 40 minutes at $150 per hour with HVAF – total $100

For the same quality, the deposition efficiency of the Kermetico HVAF process is usually higher than HVOF, but we will not even include that in the comparison.

The Typical Applications Of The High Velocity Air Fuel Fe-based Coatings

These coatings are suitable for resistance to abrasive wear, erosion, and corrosion.

They are also useful for wear and corrosion protection for hydraulic equipment as an alternative to flash chrome coatings. And as a lower cost alternative to tungsten carbide 86-10-4 coatings.

Uniform high hardness and ductility, low stress levels and low porosity lead to a substantial increase of service life for parts protected with our Fe-based coatings in comparison with other thermal spray methods, including HVOF and Detonation spraying.

Please check out other HVAF coatings` properties here.