HVAF vs. HVOF Coating Equipment Quality/Cost Comparison

How to Choose the Best HVOF Thermal Spray System

Kermetico Convertible HVAF & HVOF coating technology is the technological breakthrough that allows using the best properties of both technologies.

You do not need to choose between HVAF and HVOF anymore. Spray with oxygen when you need higher temperature or without it when you need lower oxygen content in the coating. Easy and efficient.

Find out how.

Choosing the HVOF System for Tungsten Carbide Coatings

HVOF vs. HVAF Coatings: Tungsten Carbide Quality Comparison

Kermetico Convertible HVAF & HVOF coating technology lets you define coating quality/cost ratio before you start the process.

| WC-10Co-4Cr coating features | Coating Hardness, HV300 | Coating Porosity, % | Deposition Efficiency | Young’s Modulus |

|---|---|---|---|---|

| Good HVOF | 1,050-1,250 | <0.8 | 45 – 55 | 300 |

| HVAF Economy (E) | 1,050-1,250 | <0.8 | 65+ | 400 |

| HVAF Balanced (B) | 1,250-1,350 | <0.5 | 48 – 58 | 450 |

| HVAF Ultra (U) | 1,350-1,600+ | <0.3 | 36 – 42 | 450 |

But what is the rationale behind those numbers?

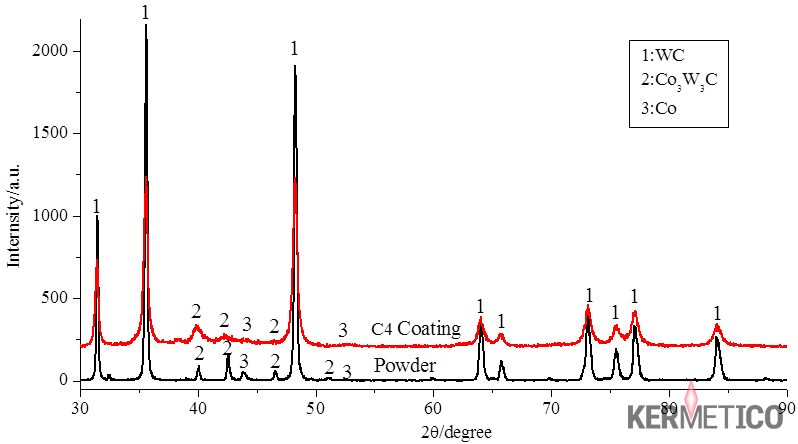

Kermetico HVAF equipment uses the energy of gas combustion in air to spray powders.

The combustion temperature in an HVAF gun is typically 1,000°C (1,830°F) lower than that in an HVOF coating system.

This lower temperature is ideal for the gradual heating of the feedstock particles of metals and cemented carbides to or slightly above the metal’s melting temperature.

The initial oxygen content in the combustion gas mixture is 5-fold lower in our HVAF process compared to any HVOF coating process.

Both factors prevent the oxidation of metals and the decomposition of carbides.

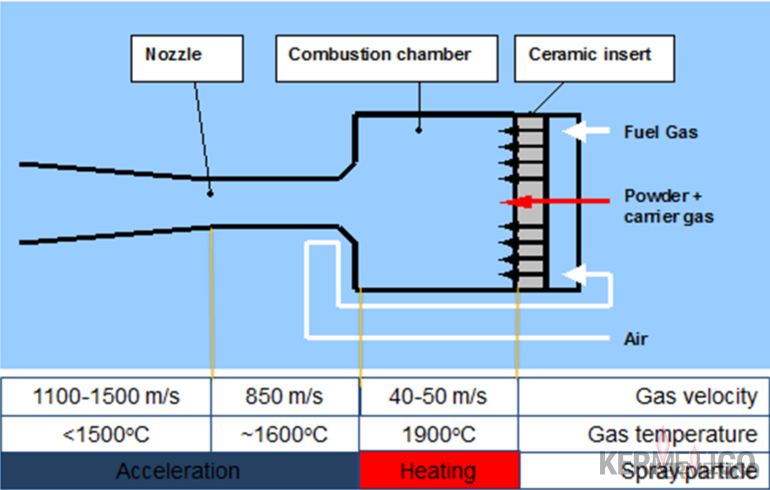

The ceramic catalytic insert is used in the combustion chamber to provide stable combustion.

The material’s acceleration occurs in the nozzle that has a large diameter.

The large diameter of the nozzle ensures that the particles do not interact with the nozzle walls, allowing the use of the longer nozzles for feedstock acceleration, typically from 800 to over 1,000 m/s (2,600-3,300 ft./sec.)

The quality and efficiency the Kermetico HVAF process is the result of the relatively low combustion temperature of an air-fuel mixture combined with the axial injection of the feedstock through the wide combustion chamber, where the low gas velocity provides sufficient time for the gentle heating of the powder particles.

These factors allow the retention of the original ductility of the powder feedstock in the applied coating, even when the hardness of the cemented carbide coating exceeds 1,600 HV300.

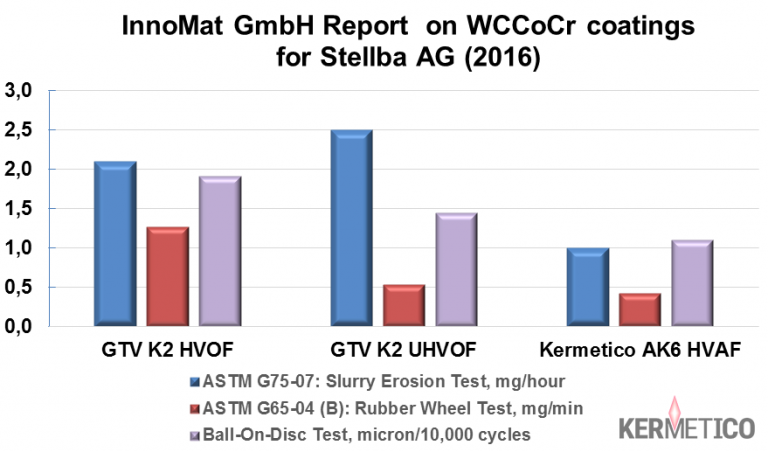

The result is higher hardness, higher ductility, higher corrosion, erosion and cavitation resistance of Kermetico HVAF coatings.

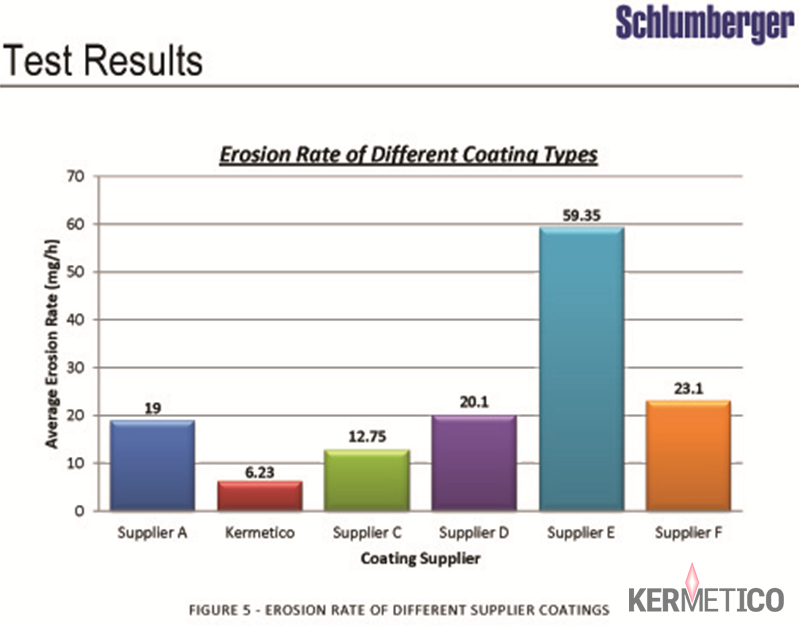

Please find below the results of a Schlumberger competitive coating evaluation conducted in 2010. The HVAF and HVOF coatings we are producing today is superior to the one evaluated in this test.

And Schlumberger is very selective in their choice of suppliers, so we were competing here with the best-of-the-breed HVOF and Detonation coatings.

Technological Stability of HVAF and HVOF Coatings

Once set up, our spray guns are technologically stable. That means that they will spray coatings with the required quality, spray rate and deposit efficiency with a remarkable range of spray parameters.

Why is that?

Our gun designs are well-calculated and made of modern materials, so our spare parts experience little wear.

Depending on the erosive properties of the feedstock material we often get over one hundred hours of spraying from a nozzle.

What about costs?

Cost Comparison of HVOF and Kermetico HVAF for Tungsten Carbide Coatings

CAPEX, New Installation Investment Costs HVAF Versus HVOF Equipment

HVAF and HVOF equipment investment cost are about the same if we speak of a one system installation.

But the Kermetico HVAF system deposits coatings 4-5 times faster (15-33 kg/hour for Kermetico HVAF as compared to 4-5 kg for HVOF), that means you could use one Kermetico HVAF system instead of several HVOF coating systems.

What if you don’t have a large volume, but you do have high diversity?

The Kermetico HVAF AK line is an all-in-one system operating several specific guns: Universal, big OD, small OD, ID, rotating ID and hand-held. This requires less investment in a Kermetico HVAF system and makes the payback period shorter.

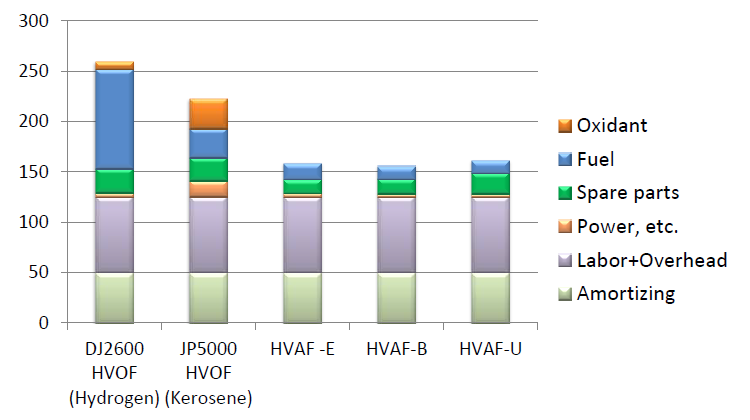

OPEX, Operating Costs HVAF vs. HVOF Coatings

The key factors of the cost advantage of Kermetico HVAF technology:

Our HVAF spray rate is 15-33 kg/hour with a deposition efficiency higher than 50%; fewer work hours means fewer hours to pay for; and with our systems, you need to spray just a fraction of the HVOF spray time

No oxygen in HVAF mode – just compressed air, which costs 10 times less

Easy-to-change specialized guns allow spraying each part in the most efficient way

The cost of consumed spare parts is 1/10 of the conventional HVOF expenses for the same work

Not impressed?

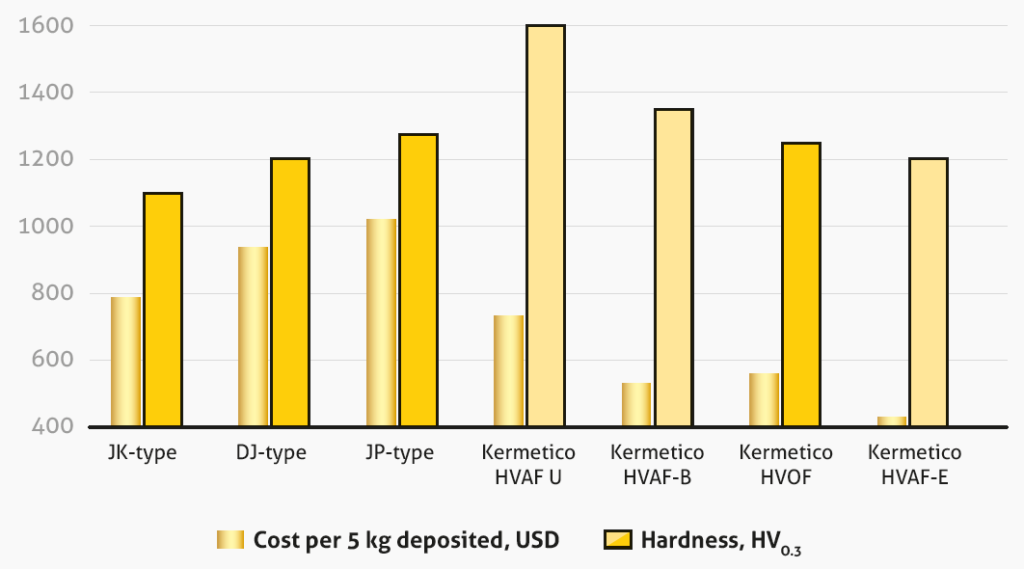

Let’s look at the cost per 5 kg (11 lbs.) of tungsten carbide coating HVOF or HVAF deposited.

Each kilogram of Kermetico deposited coating is up to two times less expensive than HVOF.

Numerous academic and practical research studies that have been conducted at different universities and job shops around the world support these data.

We will send you our calculations by request to recalculate with your in-house data.

Do you have more questions?

Is it Worthwhile to Upgrade from HVOF to HVAF?

Your investment in a new Kermetico HVAF system will pay itself back while you are spraying your second metric ton of WCCoCr.

How?

You need to buy just the Kermetico HVAF system; it fits all existing HVOF infrastructure. (Well, probably you will need to upgrade a compressor if you have a really weak one).

Your learning curve will be just a couple of weeks long – our HVAF systems are easy to use for operators familiar with HVOF.

You gain $160 per deposited kilogram of E-mode HVAF WCCoCr compared to a conventional HVOF version of the same material.

You’ll get back $160,000 per metric ton of tungsten carbide deposited, – more than enough to cover all of your expenses.

And some additional benefits come with using Kermetico HVAF as well:

- You can eliminate the blasting room – blast and spray with one setup to improve quality, shorten manufacturing time and reduce blast media consumption by a factor of 100.

- User thinner as-sprayed coating thicknesses and minimize grinding time due to the low roughness of the as-sprayed HVAF coating.

Is our Equipment Certified to Aviation Standards?

No pure HVAF equipment is certified to Aviation standards.

The Kermetico Convertible family of systems working in HVOF or HVAF mode allows spraying SAE-certified AMS 2447 and AMS 2448 coatings.

You can use the same C7 or C6 thermal spray gun spraying in HVAF mode or aviation certified HVOF mode, keeping most of our HVAF advantages.

What Could We Say of Competing HVAF systems?

Nothing.

Every word on this website is the result of Kermetico HVAF development. We do not test any competing HVAF systems and do not make comments on their qualities.

Safety

We have installed more than 60 Kermetico HVAF systems in the USA, Europe, Japan and China.

Some of the systems are at work in Universities and National Labs, but most of them are used in production thermal spray shops, including the biggest American corporations.

And each client places safety first.

But it is not just about equipment safety. Process safety is no less important.

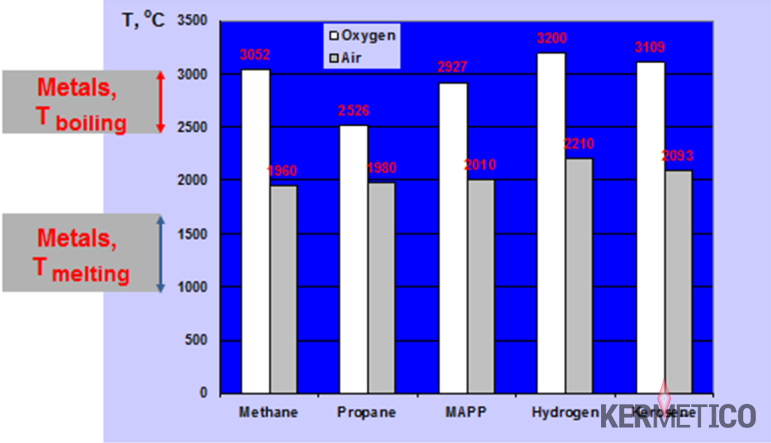

The HVOF combustion temperature is usually higher than the boiling point of feedstock, which can result in hazardous metal evaporation. It is especially dangerous during on-site operation.

The Kermetico HVAF AK combustion temperature is near most materials melting point, which preheats metals and carbides but does not evaporate them. This prevents oxidation and decomposition of the feedstock and also keeps the air clean.

Discovering New Coating Materials and Applications

The relatively low temperature and high particle speed of our HVAF process provide a broad field of research and development of new coating materials and applications.

We have already created some coatings with unusual properties for our clients: aluminum, copper, molybdenum boride, silver, tin and titanium – visit our Specialized systems page to find out more.

But there is a vast research field open for investigation right now.