The Kermetico HVAF AK5 Compact System For Spraying Metal, Alloy And Cermet Coatings Onto Thin Walls, Inside Diameters And Complex Geometries

The Kermetico HVAF AK5 system is compact and useful for thermal spraying cermet and metal coatings.

As a member of Kermetico AK family, it works with the same AK control system.

The Key Features Of Our HVAF AK5

- Spray rate – 15 kg/hour (33 lbs./hour)

- Spray powders: cermet compositions 1-15 to 5-30 microns; metals and alloys 10-30 to 10-45 microns

- Axial powder injection

- With 80 kW power, we have designed it for spraying thin walls, internal surfaces, and parts having low heat dissipation

- Fuel gas options: propane, propylene, natural gas, propane-butane, MAPP

- Air cooling (no need for a water chiller) makes the system mobile

- Sprays inside diameter 255 mm (10”) and larger

- ID rotating version for inside diameters is available

- Blast & spray operation saves 99% of blast media, 30-50% setup and preparation time

- High coating quality: high density, low level of oxidation, impermeable to gas and liquids

Spraying Alloy And Cermet Coatings Onto Thin-Walled Parts And Complex Surface Geometries

We have developed the Kermetico HVAF AK5 as an answer to a market request for a compact, low-power, high-velocity system for cermet coating. While Kermetico’s AK7 and AK6, having 200 and 130 kW of power respectively and depositing more than 26 kg (60 lbs.) per hour, are perfect for large parts, low energy dissipation surfaces need another approach.

A thermal spray process should always balance surface energy on a narrow edge between too much and too little. Too little heat will prevent or slow down coating formation. Too much heat will create excessive stress which could lead to a coating failure or even part deformation.

HVOF processes heat the substrate in the spray spot much more severely than Kermetico HVAF. (Combustion is still going on in an HVOF jet, which is not present in our well-balanced HVAF process).

The most efficient way to produce an HVAF coating is by uninterrupted heat flow through the substrate, which pre-heats the surface before the jet comes in contact with it.

Most of the full-bodied parts are massive enough to dissipate the larger guns’ HVAF jet energy and prevent excess stress formation.

But when it comes to the cermet coating of thin-walled rolls, tubes, caps, hydro turbines, steam and gas turbine vanes, as well as internal surfaces of closed vessels, high energy could become your enemy.

The regulated power of 80 kW or less for the AK5 provides the option to divide energy between feedstock powder preheating, acceleration and surface preheating.

But this is not all!

Thermal Spraying Cermet And Alloyed Metal Coatings Onto Inside Diameters (ID) 200 mm (8”) And Larger

The compact Kermetico HVAF AK5 system successfully deposits cermet and metal coatings onto internal diameters 200 mm (8”) or larger.

Two versions of the gun are available: the standard AK5 to be manipulated by a robot or other manipulator and a rotating AK5 gun to spray alloys and cermets onto inside diameters of fixed parts. Watch the video on this page to see our rotating AK5 in use.

Please also check out our AK-ID for inside diameters 80 mm (3.15”) and larger and our rotating AK-IDR for bores 100 mm (4”) and larger, up to 600 mm (2’) deep for parts that cannot easily be rotated.

The AK5 system prevents oxidation and decomposition of the feedstock and also keeps the air clean.

Do you want to know the best Part?

The Kermetico HVAF AK5 System Sprays Great Quality Cermet Coatings

The compact Kermetico HVAF AK5 system is used to deposit tungsten and chromium carbides, stainless steels, Hastelloy, Inconel and Ni-based coatings onto complex surfaces of various parts and structures.

It is a heavy-duty coating system, made to sustain harsh environments and to work long hours with high spray rates.

The AK5 spare parts consumption is ten times less than HVOF (both volume- and cost-wise).

Why is that?

The temperature of air-fuel combustion is 1,000 °C (1,830°F) lower than oxy-fuel. The parts of the gun are not heat-stressed.

Furthermore, the powder is fed axially and does not touch the nozzle walls during spraying thanks to our well-calculated gun geometry.

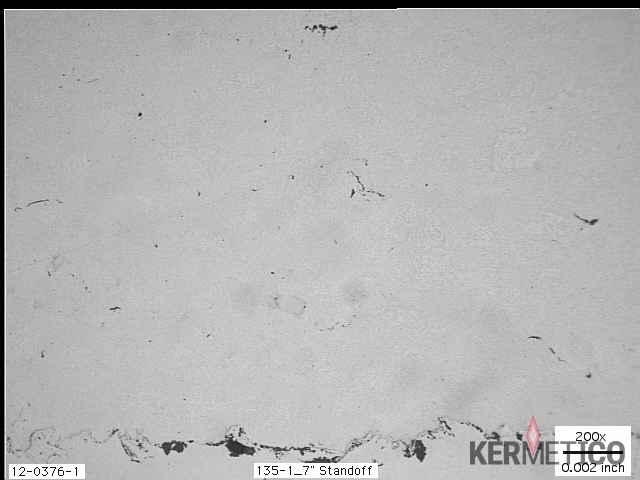

A Typical Cross-Sectional Micrograph Of The Kermetico HVAF AK5 Alloy Coating

Thermal Spray Applications For The Kermetico HVAF AK5

The Kermetico AK5 gun is designed to spray WCCoCr, CR3C2-NiCr, MCrAlY, Hastelloy-type and super stainless alloys onto a variety of parts:

- rolls, 250 mm (10”) and smaller outer diameters

- compressor rods

- valve stems

- impellers

- sleeves

- flanges

- valves

- shafts

- spindles

- turbine vanes

- hydro turbines

- pipes

Blasting And Spraying with Kermetico Equipment

Each Kermetico AK-family gun can execute blasting and spraying operations.

Prepare a part for coating, blast it with the AK gun, (it is extremely fast and uniform) change the powder feed hose and perhaps the nozzle and spray with the same gun, spending one-tenth the time for the blasting operation.

It is much faster and more accurate than manual blasting.

Using HVAF blasting for surface preparation reduces blast media consumption by 100-times compared to blasting with compressed air.

Imagine how important it is for on-site operation.

The Kermetico HVAF Process Description And Advantages

The Kermetico HVAF AK5 system deposits cermet, metal and alloyed powders, heated and accelerated by the combustion products of the air-fuel gas mixture.

When entering the gun, the compressed air cools the gun. Then the preheated air is used for mixing with the fuel for combustion.

The mixture of pre-heated compressed air and fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert.

Initial ignition of the mixture results in the heating of the insert above the mixture’s auto-ignition temperature and the hot insert then continuously ignites the mixture.

The spray powder is injected axially into a wide combustion chamber, where the gas flow is very slow, less than 40 m/s (130 ft./sec.)

The long residence time and exposure to favorable heat transfer conditions at high gas pressure, allows the powder to heat efficiently in the chamber.

As an optional tool for accurate feedstock heating, a spray operator may inject controlled amounts of a high heat conductivity gas (hydrogen, helium).

Leaving the chamber, the powder is propelled into the nozzle of chosen length and configuration, where it is accelerated to a velocity that may be from 8,00 to over 1,000 m/s (2,600 to 3,300 ft./sec.), dependent on the chosen nozzle and combustion chamber pressure.

When impacting a substrate, the spray powder particles form a coating.

The Specifications Of The Kermetico HVAF AK5 Gun

| No | Specified Characteristics | S.I.Units | U.S.Units | ||||

|---|---|---|---|---|---|---|---|

| 1 | Total heat output | 80 kW | 272,970 BTU/h | ||||

| 2 | Feedstock particle size range, microns, Carbides Metals and alloys | 1-15, 5-30 10-30, 20-45 | |||||

| 3 | Maximum spray rate | 250 g/min | 33 lbs./hour | ||||

| 4 | Fuel gas | Propane, propylene, natural gas, propane-butane, MAPP | |||||

| 5 | Consumption of compressed air | 5,240 SLPM | 185 SCFM | 7 | Consumption of fuel gas, propane | 65 SLPM | 2.3 SCFM |

| 6 | Maximum inlet air pressure | 7.4 Bar | 105 PSIG | ||||

| 5 | Consumption of compressed air | 5,240 SLPM | 185 SCFM | 7 | Consumption of fuel gas, propane | 65 SLPM | 2.3 SCFM |

| 8 | Maximum inlet fuel pressure | 7.4 Bar | 105 PSI | ||||

| 9 | Consumption of powder carrier gas, N2 | max 20 SLPM | max 0.7 SCFM | ||||

| 10 | Gun dimensions | 152 (229)x 80×80 mm | 6(9) x 3.15×3.15 inch | ||||

| 11 | Gun weight with handle | 3kg | 6.7 lbs. | ||||

| 12 | Average thrust during gun operation | 3.6 kg | 7.9 lbs. | ||||