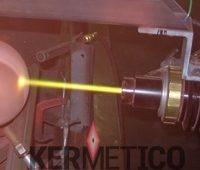

WC-10Co-4Cr Tungsten Carbide Cobalt Chrome HVAF Thermal Spray Coating Properties, Structure And Applications WC-CoCr 86/10/4 powder is used for the deposition of wear resistant coatings. Kermetico HVAF tungsten carbide coatings have excellent resistance to sliding wear, abrasion, cavitation, and erosion. They are tough and reveal good fatigue and impact resistance, excellent corrosion resistance except in high pH environments and in hydrofluoric acid solutions. Kermetico…