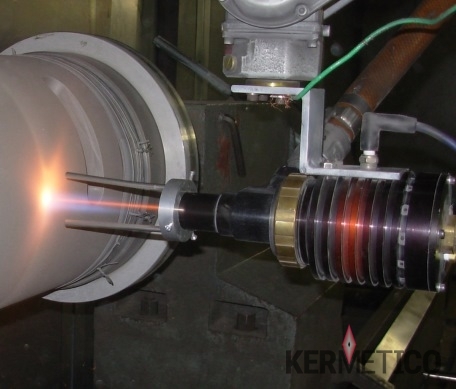

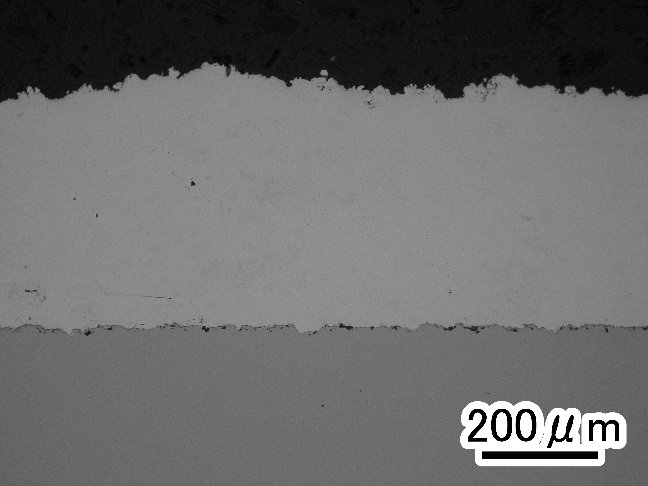

The AK-ID Rotating Gun To HVAF Spray Metals And Carbides Onto Bores And Internal Diameters High Velocity Air-Fuel Spraying (HVAF) is an advanced method for the deposition of quality carbide and metallic alloy coatings to protect internal surfaces of industrial equipment against severe wear and corrosion. The Kinetic Surface AK-IDR Rotating HVAF Spray Gun The ID rotating HVAF spray torch is a recent development…