AK7 – An HVAF Gun For Spraying Coatings Onto Large Parts, For Research And Development

The Kermetico AK7 HVAF Gun for Large Part Coatings

Key Features:

- Spray rate – 33+ kg/hour (73+ lbs./hour)

- Spray powders, 3-15 to 15-45 microns

- tungsten carbide

- chromium carbide

- pure metals

- alloys (from stainless steels to MCrAlY)

- Fuel gas choices:

- propane

- propylene

- natural gas

- propane-butane

- MAPP gas

- Axial powder injection

- Economy mode for the highest deposit efficiency (65+%)

- Balanced mode to spray WCCoCr with 48-58% deposit efficiency, 1,250-1,350 HV300 hardness

- Ultra mode for WC-86Co-10Cr-4 coating with the hardness of 1350- 1,600+ HV300

- Blast & spray operation saves 99% of blast media, 30-50% setup time

- Air cooling (no need for a water chiller) makes the system mobile friendly

- High coating quality: high density, low level of oxidation, impermeable to gas or liquids

- High technological efficiency – it is hard to make a mistake with this gun

We developed the Kermetico AK7 HVAF system in 2006.

Over the years we improved and optimized its design substantially based on the gun performance in our spray shops.

Each part and assembly of the gun, each new improvement went through intensive scrutiny while spraying tons of cemented carbides and different metals.

Now it is a very straightforward and robust HVAF gun with many hardware variations and a good record of working parameters and results.

The Kermetico AK7 HVAF gun created a basis for later development of lower power systems and internal diameter spraying guns.

Cost Effective High Velocity Thermal Spray Equipment

What makes the Kermetico AK7 system cost effective compared to all alternatives, including HVOF, Cold Spray, Kinetic Spray or Laser Cladding?

Let us compare the HVAF costs to spray tungsten carbide with the popular HVOF guns

- Spray rate over 33 kg per hour with higher than 65% deposition efficiency (in Economy mode); with HVAF AK7 you have to spray just a fraction of HVOF spray-time; fewer work hours means fewer hours to pay for and lower overhead

- No oxygen– just compressed air, which costs 8-15 times less

- Heating of spray particles in the long combustion chamber is extremely efficient; it reduces total energy consumption per kilogram of deposited coating 5-10-times

- Axial powder supply and a lower combustion temperature will allow you to spend ten times less on the spare parts

- Blasting and spraying with the same gun allows removing the extra operation which saves time and money

- If your spec allows, you can halve your cost just halving the coating thickness – it works

A High Quality, High Spray Rate HVAF Gun For A Job Shop, Especially For One Spraying Large Parts

The AK7 HVAF gun is designed to deposit metal and cermet coatings onto external surfaces of various components and structures.

It is heavy-duty equipment, made to sustain harsh environments and to work long hours with high spray rates.

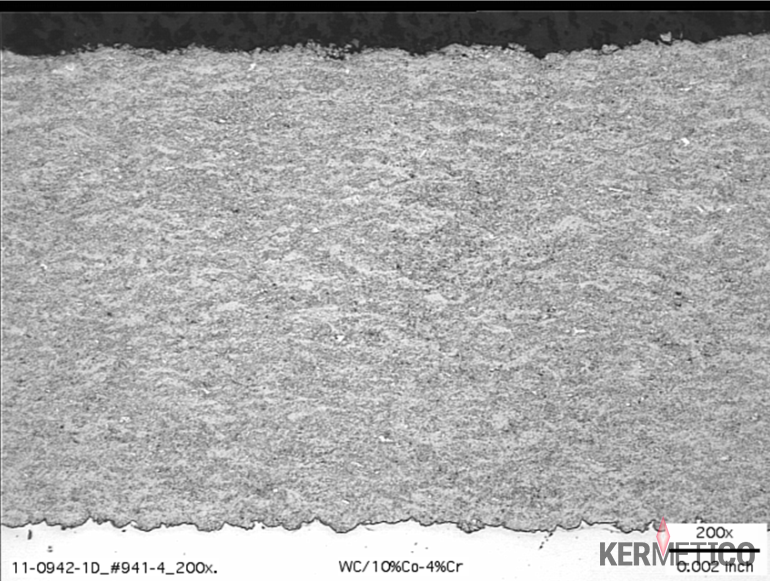

A Microstructure of an AK7 HVAF WC-Co-Cr 86/10/4: No Gas Permeability at 300 PSI, Hardness 1,450±60 HV300

HVAF Thermal Spray Coating Applications

Kermetico HVAF AK7 equipment is comfortable spraying large rolls, cyclones and vessels. It can also be useful for thermal spray coating of other parts.

The Kermetico AK7 System Is Perfect For Research And Development Of High Velocity Thermal Spray Processes And Coatings

The AK7 gun works reliably with LPG fuels, such as propane, propane-butane, propylene and MAPP-gas, as well as with methane and natural gas.

Typical inlet air pressure to the gun is 80-95 PSI, while the gun performs well within 45-120 PSI inlet air pressure range.

Regular consumption of propane or propylene is 120-190 SLPM (as gas), corresponding to 200- 320 kW of equivalent power.

While we have operated the gun at 212 SLPM of propane (350 kW), there was no evidence that this was its power limit.

The option for hydrogen injection provides better particle temperature control and prevents materials oxidation

The AK7 system can work with hydrogen injection. The control of hydrogen injection provides an additional tool for particle temperature regulation due to high thermal conductivity of hydrogen, as well as additional protection of the spray material from oxidation.

A variety of hardware setups for different powder materials and different process requirements.

The AK7 gun has many developed nozzle, injector and combustion chamber setups for research and development of different spray materials.

This gun may also be used for erosion testing of materials utilizing the hot jet of combustion products alone or with abrasive particles accelerated and heated by the gun.

Blast And Spray With The Kermetico High Velocity Guns

Each Kermetico AK HVAF gun can be used in blast and spray operations.

You can eliminate blasting and masking for blasting in a different booth. Just prepare a part for coating, blast it with any AK gun (it is extremely fast and uniform) and spray with the same gun, spending 10x less time for the blasting operation.

It is much faster and more accurate than manual blasting.

Furthermore, using HVAF blasting for surface preparation reduces blast media consumption by 100-times compared to blasting with compressed air.

We have done this with thousands of parts in our proof-of-concept job shop in Benicia, California, USA.

HVAF Process Description and Advantages

The AK7 HVAF system sprays powders, heated and accelerated by the air-fuel gas combustion products. When entering the gun, the compressed air cools the gun.

Then the preheated air is used for mixing with the fuel for combustion. The mixture of preheated compressed air and the fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert.

Initial ignition of the mixture by a spark plug results in the heating of the insert above the mixture’s auto-ignition temperature and the hot insert continuously ignites the mixture.

The spray powder is injected axially into a wide combustion chamber, where the gas flow is very slow, less than 40 m/s(131 ft./sec.)

Having a long residence time and being exposed to favorable heat transfer conditions at high gas pressure, the powder is efficiently heated in the chamber.

As an optional tool for accurate heating controlled amounts of a high heat conductivity gas (hydrogen, helium) may be injected.

Exiting the chamber the powder is propelled into the nozzle of chosen length and configuration where it is accelerated to a velocity that may be from 800 m/s to over 1,000 m/s, dependent on the chosen nozzle and combustion chamber pressure.

When impacting a substrate the spray powder particles form a coating.

The Kermetico HVAF AK7 Gun Specifications

| No | Specified Characteristics | S.I.Units | U.S.Units |

|---|---|---|---|

| 1 | Total heat output | 165-200 kW | 561,000-682,000 BTU/h |

| 2 | Spray powder size ranges, µm WC- and Cr3C2-base Metal alloys | 3-20, 5-30, 15-45 10-30, 15-45 | |

| 3 | Spray rate | 550+ g/min | 73+ lbs./hour |

| 4 | Fuel gas | Propane, propylene, natural gas, propane-butane, MAPP | |

| 5 | Optional secondary gas | Hydrogen, helium | |

| 6 | Consumption of compressed air* | 7,300 SLPM | 258 SCFM |

| 7 | Maximum inlet air pressure | 10.5 Bar | 150 PSIG |

| 8 | Consumption of fuel gas, propane* | 100-190 SLPM | 3.5-6.7 SCFM |

| 9 | Maximum inlet fuel pressure | 11.6 Bar | 165 PSI |

| 10 | Consumption of powder carrier gas, N2 | max 25 SLPM | max 0.9 SCFM |

| 11 | Consumption of optional secondary gas, H2 | max 20 SLPM | max 0.7 SCFM |

| 12 | Gun dimensions | 254 (305) x 127 x 127 mm | 10 (12) x 5 x 5 inch |

| 13 | Gun weight with fixture and nozzle | 5.2 kg | 11.5 lbs. |

| 14 | Average thrust during gun operation | 7.5 kg | 16.5 lbs. |

(*) During gun startup, the consumption of air and fuel is up to 30% higher than during operation.