The High Velocity AK6 System For Spraying Cromium And Tungsten Carbide Coatings

Key Features:

Spray rate for a tungsten carbide coatings – 28 kg (62 lbs.)/hour

- Spray powders: tungsten carbide, chromium carbide 1-20 to 15-30 microns (if you need to spray HVOF-cut powders, please refer to our Convertible systems)

- Axial powder injection

- Fuel gas options: propane, propylene, natural gas, propane-butane, MAPP

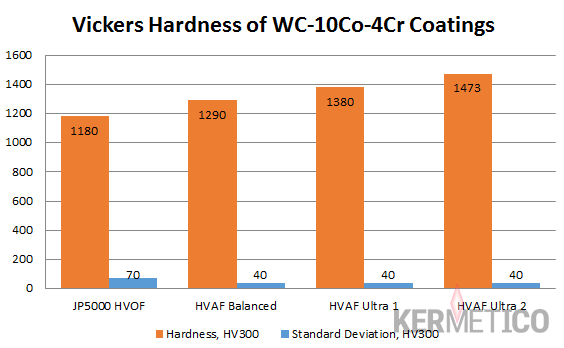

- Balanced mode for 45-50% deposit efficiency, hardness 1,250-1,350 HV300

- Ultra-mode for WC-10Co-4Cr coating hardness up to 1,600+ HV300

- Blast & spray operation saves 99% of blast media, 30-50% setup and preparation time

- Air cooling (no need for a water chiller) makes the system on-site friendly

- High coating quality: high density, low level of oxidation, impermeable to gas and liquids

AK6 is a very simple and technologically efficient gun with a good record of high quality carbide deposition results. If you need a universal equipment, please check our full family of the AK guns.

The Highest Tungsten Carbide Coating Quality

The Kermetico AK6 system sprays tungsten carbide coatings better than any other alternative, including HVOF, or other HVAF systems.

Look at the chart showing quality vs. deposition efficiency.

| AK6 WCCoCr-86/10/4 spray mode | Coating Hardness, HV300 | Coating Porosity, % | Deposition Efficiency, % |

|---|---|---|---|

| Balanced (B) | 1,250-1,350 | <0.5 | 45 – 50 |

| Ultra Quality (U) | 1,350-1,600+ | <0.3 | 36 – 42 |

With this spray system, we are not limited to the “best coating possible.”

We can choose how to spray:

- spray the highest coating quality HVAF U-mode to get high-hardness ductile non-porous abrasion and cavitation resistant coatings

- or choose HVAF Balanced mode to gain a competitive edge both in cost and quality

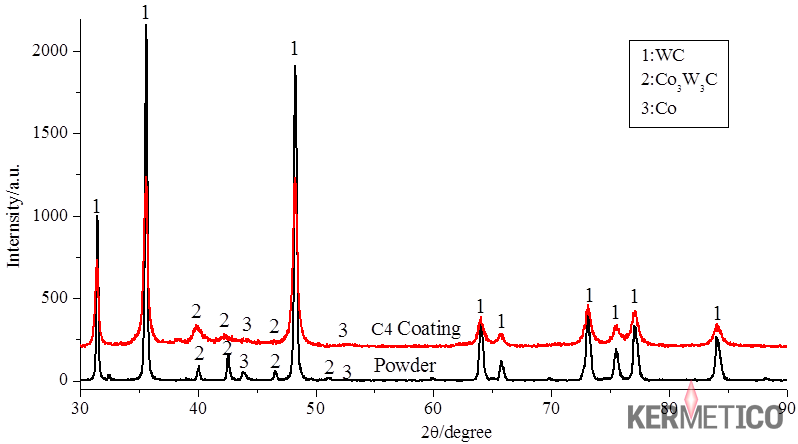

But how do HVAF Balanced and Ultra modes provide such excellent results?

As Mr. Kumar has shown in his article “Effect of Spray Particle Velocity on Cavitation Erosion Resistance Characteristics of HVOF and HVAF Processed 86WC-10Co-4Cr Hydro Turbine Coatings”:

- HVAF coatings exhibit lower porosity levels, higher hardness, toughness, and superior cavitation resistance compared to HVOF coatings for the same spray powder conditions. The higher toughness values, as well as the consistency in scratch depth results in HVAF coatings, support these findings.

- HVAF coatings sprayed with higher spray velocities result in improved toughness and cohesiveness of splat layers of the coating that provides better cracking resistance under bubble implosions.

- The superior cavitation resistance property of HVAF coatings was thus attributed to the increased hardness, toughness, and effective WC-matrix interface cohesiveness during the prolonged cavitation exposure periods.

- The particle velocity appears to play an important role in achieving a dense coating with an increased level of compressive stresses and gives rise to higher elastic strain energy during indentation.

But it is not the end of the story.

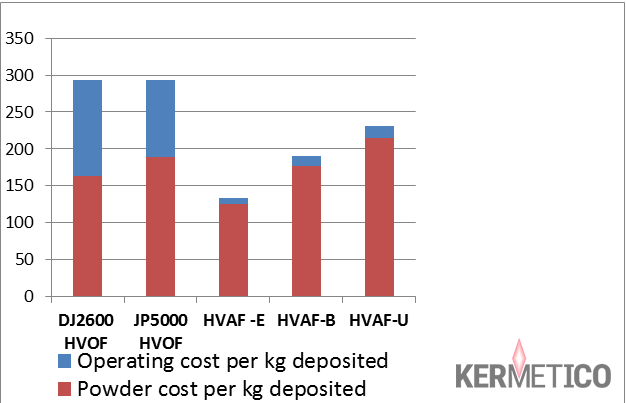

A Cost Comparison Of HVAF And HVOF Tungsten Coatings

What is the bottom line?

This specialized HVAF equipment is designed to thermal spray tungsten and chromium carbide coatings. It produces the same quality coating with a lower cost or a high-quality coating with the same or lower cost than HVOF.

Having a $160 advantage per a kilogram of material deposited, the Kermtico HVAF system pays back your investment after depositing its first metric ton of tungsten carbide.

What is the difference between Balanced and Ultra modes?

- Particle speed in B-mode is higher than of conventional HVOF, which results in harder coatings with better abrasion and cavitation resistance.

- Ultra-coating mode provides spray particles with such speed and temperature that it decreases deposit efficiency dramatically but creates a coating close to theoretical limits.

Each mode minimizes oxidation and decarburization of the tungsten carbide particles.

Kermetico HVAF AK6 Chromium And Tungsten Carbide Сoatings

The AK6 HVAF gun can be used to deposit tungsten coatings onto internal or external surfaces of various parts and structures.

It is a heavy-duty system, made to endure harsh environments and to work long hours with high spray rates.

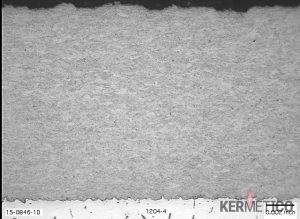

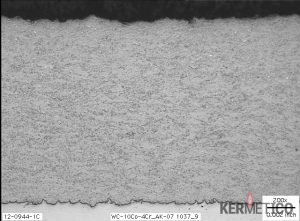

Typical Cross-Sectional Micrographs Of Kermetico HVAF AK6 Tungsten Coatings

AK6 Thermal Spray Applications For Cemented Carbide Coatings

We have optimized the Kermetico AK6 system to spray:

Hard Electroplated Chrome replacement is a fast growing area for the implementation of our HVAF technologies.

We can deposit chromium carbide coatings onto vessels and heat exchangers; it can also be successfully used for the coating of other parts.

In our shop, we have applied chromium carbide layers onto thermowells, ball valves, ash hoppers, auger flights and bearing fits, process rolls, turbine clamp strips and blades.

Blasting And Spraying With The Kermetico High Velocity Guns

Each Kermetico gun can be used in blasting and spraying operations.

You can eliminate blasting and masking for blasting operations in a different booth. Prepare a part for coating, blast it with an AK gun (it is extremely fast and uniform) change the powder feed hose and perhaps the nozzle and spray with the same gun, spending 10x less time for the blasting operation.

Hot grit blasting is much faster and more accurate than a conventional air blasting.

The best part?

Using HVAF blasting for surface preparation reduces blast media consumption by 100-times compared to blasting with compressed air in a blasting cabinet.

We have done this with thousands of parts in our proof-of-concept job shop in Benicia, USA.

HVAF Process Description And Advantages

The AK6 HVAF equipment sprays powders, heated and accelerated by the combustion products of the air-fuel gas mixture.

When entering the gun, the compressed air cools the gun. Then the preheated air is used for mixing with the fuel for combustion.

The mixture of compressed air and fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert.

Initial ignition of the mixture results in the heating of the insert above the mixtures’ auto-ignition temperature and the hot insert then continuously ignites the mixture.

The spray powder is injected axially into a wide combustion chamber, where the gas flow is very slow, less than 40 m/s (130 ft./sec.)

The long residence time and exposure to favorable heat transfer conditions at high gas pressure, allows the powder to heat efficiently in the chamber.

As an optional tool for accurate heating, controlled amounts of a high heat conductivity gas (hydrogen, helium) may be injected. Leaving the chamber, the powder is propelled into the nozzle of chosen length and configuration, where it is accelerated to a velocity that may be from 800 m/s to over 1,000 m/s (2,600-3,300+ ft./sec.), dependent on the chosen nozzle and combustion chamber pressure. When impacting a substrate, the spray powder particles form a coating.

The Kermetico HVAF AK6 Gun Specification

| No | Specified Characteristics | S.I.Units | U.S.Units |

|---|---|---|---|

| 1 | Total heat output | 130 kW | 442,000 BTU/h |

| 2 | Feedstock particle size range, microns, Carbides Metals and alloys | 3-20, 5-30, 11-45 | |

| 3 | Maximum spray rate | 28 kg/hour | 62 lbs./hour |

| 4 | Fuel gas | Propane, propylene, natural gas, propane-butane | |

| 5 | Optional secondary gas | Hydrogen, Helium | |

| 6 | Consumption of compressed air* | 6,650-8,500 SLPM | 235-300 CFM |

| 7 | Maximum inlet air pressure | 10.5 Bar | 150 PSIG |

| 8 | Fuel gas consumption, propane | 70-100 SLPM | 2.5-3.5 SCFM |

| 9 | Maximum inlet fuel pressure | 11.4 Bar | 165 PSI |

| 10 | Consumption of powder carrier gas, N2 | max 25 SLPM | max 0.9 SCFM |

| 11 | Consumption of optional secondary gas, H2 | 5- 20 SLPM | max 0.7 SCFM |

| 12 | Gun dimensions | 254 (305) x 127 x 127 mm | 10 (12) x 5 x 5 inch |

| 13 | Gun weight with gun mount and nozzle | 5.2 kg | 11.5 lbs. |

| 14 | Average thrust during gun operation | 7.5 kg | 16.5 lbs. |

(*) During gun startup, the consumption of air and fuel is up to 30% higher than during operation.