HVOF Equipment For Sale: Convertible Thermal Spray Coating Systems

- Kermetico Convertible equipment offers the final solution for the HVAF vs. HVOF discussion.

- You no longer need to choose between standardized HVOF equipment and our efficient HVAF processes.

- You can use our Convertible HVAF & HVOF equipment spraying coatings in HVOF mode conforming to legacy HVOF standards or in an HVAF mode depositing higher-quality and less expensive coatings.

- Our gas fuel HVOF allows spraying corrosion and wear resistant coatings with the best quality and cost.

A Description Of Our Gas-Fuel HVOF Equipment And Thermal Spray Coating Process

- Kermetico Gas-fuel High-Velocity Oxygen Fuel HVOF equipment utilizes continuous combustion of gaseous fuel, oxygen and air to generate a high velocity gas stream propelling a powder feedstock towards the surface to be coated.

- The powder partially melts in the stream and deposits on the substrate.

- The resulting coating has low porosity and high bond strength.

- Kermetico C equipment works in HVOF mode at a particle temperature up to 1,700°C (3,100°F) and accelerates the particles sized at -45/+15 microns to 700-850 m/s (2,300-2,800 ft./sec.).

The HVAF Coating Mode

- Working in High Velocity Air-Fuel mode, our Convertible equipment deposits coatings using continuous combustion of gaseous fuel and air, propelling metal or carbide powders towards the substrate.

- The feedstock is being heated below its melting point, and it is much less oxidized or decomposed compared to coatings made with conventional Tafa-like HVOF equipment.

- Those features allow us to spray fine particles (5-20, 15-30 microns) accelerated to over 1,000 m/s (3,280 ft./sec.)

- Smaller particles are difficult to spray with conventional HVOF equipment due to the high oxidation rate and partial evaporation in the high temperature environment.

- Our Convertible equipment features a lower combustion temperature even in HVOF mode.

- HVAF mode excludes evaporation and minimizes oxidation, leading to excellent coating properties.

HVOF Tungsten Carbide Coating Standards

Depositing certified tungsten carbide powders with Kermetico C HVOF equipment is 100% compliant with all existing HVOF standards for tungsten carbide coating applications, from aviation-specific SAE AMS 2447, 2448, 7886 to proprietary Schlumberger, Weatherford, NOV or Siemens standards.

The Choice Of Hybrid High Velocity Thermal Spraying Equipment

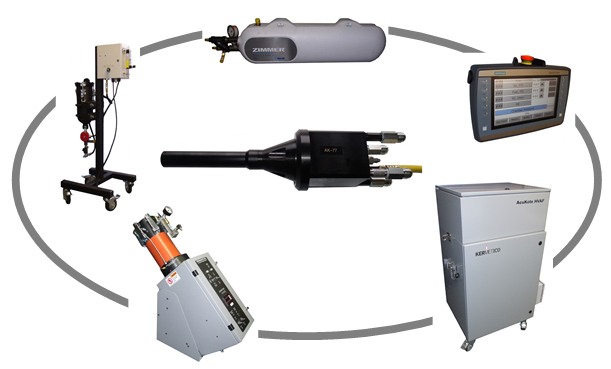

Our HVAF-HVOF equipment includes:

- One or more spray guns

- Control console equipped with a PLC and an industrial mobile computer

- A powder feeder

- A gas vaporizer

- An optional grit feeder for hot grit blasting.

As you see, there is no water chiller in setup, and the reason is – all our HVOF equipment is air-cooled.

It provides not just higher mobility and robustness – we use a greater share of the power for powder acceleration, which makes our systems more energetically efficient.

Why Should One Care Of Adding HVAF To HVOF Equipment At All?

The Kermetico AK systems deposit the same specification coatings with a spray rate that is 5-6 times higher and at a 20-30% higher deposition efficiency, which leads to ½ of the HVOF cost and can provide a coating of higher quality when needed.

Choosing Kermetico AK, a manufacturing shop gains a 50% cost advantage over HVOF competitors and additional coating quality superiority as a bonus.

The Thermal Spray Industry uses the HVAF process infrequently because it is not consistent with most HVOF standards. (AF systems work best on fine powders, while some specifications require 15-45 or 20-53 μm powder sizes).

The Kermetico C (C for Convertible) equipment family operates in either mode.

Kermetico C uses gas fuel, oxygen and air to spray HVOF powders consistent with HVOFstandards, and it works in pure HVAF mode to deposit ductile, high-hardness (1400-1600+ HV300, 6% deviation), non-permeable, smooth as-sprayed tungsten carbide coatings.

Our HVOF mode Convertible is compliant with HVOF specifications and still lets you halve operating costs. The HVAF mode offers you greater savings or allows you to create coatings with properties superior to any HVOF spec – the choice is yours.

Kermetico HVAF+HVOF Equipment Compared To Other Systems

The Kermetico convertible equipment is a unique family of HVAF&HVOF guns, designed with hot catalytic ceramic inserts, igniting the air-fuel + oxygen mixture in the combustion chamber and axial feeding of the feedstock.

HVAF Coating Quality

The quality and efficiency of the Convertible equipment is the result of the relatively low combustion temperature of air-fuel or oxy-fuel mixtures combined with the axial injection of the feedstock through the long combustion chamber, where the low gas velocity provides sufficient time for the powder particles gradual heating.

The material’s acceleration occurs in the nozzle that has a large diameter.

The large diameter of the nozzle is needed to ensure that the nozzle walls do not interact with the powder particles, allowing the use of a nozzle that is as long as needed for feedstock acceleration, typically from 800 to over 1,000 m/s (2,600 – 3,300+ ft./sec.).

The Catalytic Insert is used in the combustion chamber to provide a broad range of stable combustion parameters.

The heating of the spray particles in the combustion chamber occurs at high pressure, where heat transfer is the most efficient.

The size of the chamber provides a long residence time for the spray particles to heat. Thus the energy transfer efficiency is increased noticeably compared to other high-velocity spraying methods, resulting in much higher spray rates.

Heating efficiency is a primary reason for the lower cost of Kermetico coatings.

The large diameter of the nozzle eliminates its length limitations, known to other guns. The spray particles can be accelerated up to the gas velocity.

The diameter of the spray particle jet is several times smaller than the nozzle diameter.

The influence of the nozzle walls on the spray particle velocity is negligible, providing even acceleration of the powder particles and improved consistency of the coating structure.

Combustion Chamber Pressure Measurements And Safety Interlocks

The C guns provide the means for the measurement of the combustion chamber pressure, which is an essential parameter of the spray process.

The data from the combustion chamber pressure transducer are used for the detection of the powder carrier gas flow during the gun ignition process.

This allows creating a safety interlock for preventing gun ignition if no flow of carrier gas was detected, preventing the possibility of a flash-back into the powder hose and flow of combustible gases into the powder feeder.

Hybrid HVAF-HVOF Control Equipment

The Kermetico C Control Console consists of a Mobile Touch-Screen Industrial Tablet, a Controller, a Gun Ignition box and a set of cables and hoses.

The Mobile Touch-Screen Tablet is typically used inside the control room – on the wall (a wall-mounting bracket is provided) or laid on the table and can be easy carried around the Operator room and into the spray booth as needed.

The Controller (control cabinet) is typically placed inside the spray booth. The Tablet connects to the Controller with a 25’ (7.5 m) long cable (other cable lengths are available upon request).

The Mobile Touch-Screen Industrial Tablet

The Mobile Touch-Screen Industrial Tablet is a rugged industrial computer with the Microsoft Windows CE operating system – the OS is specifically designed to work with an industrial PLC, providing better reliability than current versions of Windows 8/10 used in industrial computers for general use.

The Tablet includes a wide format touch screen (8” x 4.5”) and “Soft Touch” buttons for process control (start/stop of the gun, powder feeder, and other functions).

Its memory is expanded with an added memory card (replaceable), and an additional USB port allows for the installation of flash memory for data acquisition, quick re-installation of a lost program or future programs updates, as well as for connection to another computer or compatible electronic devices.

The Tablet has a hard-wired illuminated E-stop and the whole device with its connected cable is rated IP67 (dustproof and waterproof when submerged under water for 30 minutes).

The Tablet Touch-Screen Interface through the integrated PLC provides all of the functions necessary for the operator to control the spray gun, powder feeder, and peripheral devices that are connected to the PLC’s electronic blocks (The PLC and electronic blocks are housed in the Controller).

The Tablet program contains a number of operating windows, providing an operator interface for:

- setting the gun parameters

- monitoring them in a real-time graphical mode

- controlling the combustion chamber pressure, inlet and outlet pressure of gases and mass flow of gases

- setting and displaying of the warning and safety shutoff alarms

- setting and monitoring of the powder feeder parameters

- adjustable settings for the “gun startup” and “powder feeder startup” carrier gas flow

- adjustable settings for ignition parameters

- displaying of running operations

- uploading of pre-programmed parameters (default and customer-saved)

- downloading of new parameters, etc

The Controller

The Controller consists of two cabinets mounted together and isolated from each other:

- A General Use cabinet with devices controlling the air and carrier gas (nitrogen) consumption and the electronic control block (with the PLC, electronic blocks, power supplies, relays, etc.) The cabinet enclosure is air-purged (positive pressure protection).

- The Fuel cabinet with devices controlling propane/propylene and hydrogen consumption; all devices and electrical connections certified to Class 1 Group A, B, C, D Division 1. The cabinet enclosure is air-purged (positive pressure protection).

The Controller includes:

- Independent combustion air and cooling air inlets (with an option for 2-compressor setup)

- Electronic proportional valve for combustion air pressure control as well as a mass-flowmeter for combustion air flow monitoring

- Manual pressure regulator for cooling air pressure control

- Electronic proportional valve for fuel pressure control, as well as a mass-flowmeter for fuel flow monitoring; includes two calibrations – for propane and propylene

- Mass-flow-controller for a carrier gas

- Mass-flow-controller for hydrogen (optional for hydrogen injection mode)

- Setup for purging the hydrogen line with nitrogen

- Combustion chamber pressure monitoring with a nitrogen-purged line

- Inlet and outlet pressure control for all gas lines

- Interlock for preventing gun ignition in the absence of nitrogen flow to the gun

- Interlock for preventing hydrogen flow if nitrogen pressure is lower than hydrogen pressure

- Full remote control of the powder feeder

- Setup for automatic pressure release of the powder feeder canister for shutdown

- Interface for remote control

- E-stop interface for external devices (robot, etc.)

Other functions and device settings are available upon request.