HVAF And HVOF Control Console With A Tablet Operator Control

The HVAF And HVOF Control Console

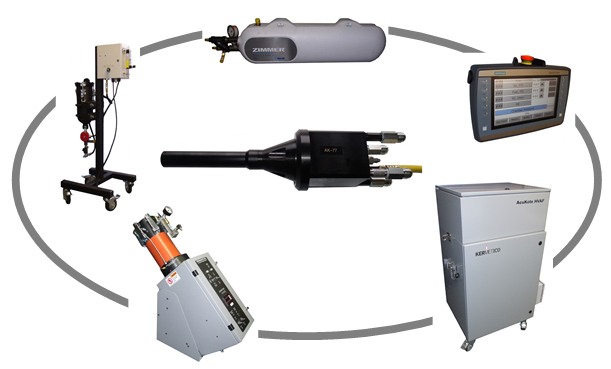

Our Control Console consists of an Operator Tablet, Controller, Gun Ignition box and a set of cables and hoses.

The Operator Tablet is typically mounted on the wall of the operator room (a wall-mounting bracket is provided) or placed on a work table and can easily be carried around the control room and into the spray booth as needed.

The Controller is designed to be located inside the spray booth.

The Tablet and Controller are connected with a 7.5 meter (25-foot) long cable (other cable lengths are available upon request).

The system can be equipped with an optional interface to monitor and troubleshoot equipment at any authorized internet-connected device.

The IP67 Mobile Touch-Screen Tablet, Dustproof And Waterproof

The Operator Tablet is a rugged industrial computer with the Microsoft Windows CE operating system – the OS specifically designed to work with an industrial PLC. The Tablet features a 8” x 4.5” wide format touch-screen and “Soft Touch” buttons (which are illuminated industrial membrane keys) used for process control (start/stop of the gun, powder feeder, and other devices).

The Tablet has a hard-wired illuminated E-stop.

The whole device with the cable connected is rated IP67 (dustproof and waterproof when submerged under water up to 30 minutes).

The Tablet Touch-Screen Interface through the integrated PLC provides all of the functions necessary for the operator to control the spray gun, powder feeder, and peripheral devices that are connected to the PLC’s electronic blocks (The PLC and electronic blocks are housed in the Controller).

The Tablet program provides many operating windows, giving an operator the interface for setting and monitoring:

- the gun spray parameters

- powder feeder and peripheral devices parameters

- warning and safety shut-off alarms and interlocks

- as well as a window for saving and uploading spray parameter files

The HVAF+HVOF System Controller With Partitioned Cabinets

The Controller consists of two cabinets mounted together and isolated from each other:

- General use compartment with devices controlling the air and carrier gas (nitrogen); the electronic control block (with the PLC, electronic blocks, power supplies, relays, etc.) is also located in this cabinet.

- The fuel compartment with devices controlling fuel and hydrogen; all devices and electrical connections certified to Class 1 Group A, B, C, D Division 1.

The controller is set on 4 wheels, 90 kg (200 lbs.) capacity each.

The Controller Specifications

| Feature | S.I. Units | U.S. Units |

|---|---|---|

| Total air flow, maximum | 11,400 SLPM | 400 CFM |

| Air pressure control | ||

| Combustion air | 1.4-10 Bar, accuracy +/- 0.05 Bar; inlet max. 10 Bar | 20-150 PSI, accuracy +/- 0.7 PSI; inlet max. 150 PSI |

| Cooling air | 3.4-10 Bar, accuracy +/- 0.4 Bar; inlet max. 14 Bar | 50-150 PSI, accuracy +/- 2 PSI; inlet max. 200 PSI |

| Fuel type | Propane, propylene, MAPP-gas, natural gas | |

| Fuel flow | 250 SLPM (propane) 350 SLPM (nat. gas) at 6-10 Bar | 9 CFM (propane) 12.4 CFM (nat. gas) at 90-140 PSI |

| Fuel pressure control | 1.4 -10 Bar, accuracy +/- 0.05 Bar; inlet max. 11 Bar | 20-150 PSI, accuracy +/- 0.7 PSI; inlet max. 165 PSI |

| Nitrogen | 0- 50 SLPM, inlet pressure max. 14 Bar | 0- 2 CFM, inlet pressure max. 200 PSI |

| Hydrogen | 0- 50 SLPM, max inlet pressure 14 Bar | 0- 2 CFM, max inlet pressure 200 PSI |

| Power | 108-130 VAC (5 amps) or 210-240 VAC (3 amps), 50/60 Hz, 1-phase | |

| Ignition box outlet power | 110 VAC, 50/60 Hz | |

| Weight, Controller | 112 kg | 250 lbs. |

| Weight, Tablet | 1.5 kg | 3.5 lbs. |

| Dimensions, Tablet (suitable for wall-mount and bench-top use) | 300x275x62 mm | 12” x 11” x 2.5” |

| Dimensions, Controller | 712x 610×966 mm | 28” x 24” x 38” |

The Kermetico HVAF Control Console Components: Ignition Box And Hoses

The Ignition box includes a high-voltage transformer enclosed in the NEMA 4 aluminum enclosure for mounting on the robot at a maximum distance of 600 mm (2-feet) from the gun.

The second electrode is grounded to prevent damage to the robot in the case a transformer or ignition wire is damaged.

All hoses have a satisfactory rating for pressure and material for each gas line.

The powder hose is thick wall tubing with grounded static-dissipating strips.

Powder hose fittings are “field-attachable” (reusable in the spray shop/lab).

Combined with the features of the High-Pressure Powder Feeder, the supplied powder feed hose provides reliable feeding of very fine powder distributions (even -10/+1 micron) with the relatively low flow of nitrogen carrier gas – under 22 SLPM.

Reliable spraying of very fine powders is an essential advantage of Kermetico HVAF equipment.

With the same jet, fine particles are accelerated to a higher velocity than larger particles and they are heated through to a higher temperature than coarse particles, thereby expanding the technological windows of the Kermetico HVAF process.

The High-Pressure Thermal Spray Powder Feeder

The HVAF powder feeder is a rotary powder feeder, which is additionally equipped with an automatic pressure relief valve assembly, activated from the control console.

The heart of the feeder’s electrical controls is a digital closed-loop controller, offering precise and accurate wheel speed.

The startup and the shutdown of the feeder and the wheel RPM are remotely controlled from the control console.

The feeder has an option for manual control.

Interlocks from the control console provide a safety shutdown when the wheel RPM is abnormally low as compared to preset values, no carrier gas flow detected at the gun during ignition, or carrier gas pressure is lower than the hydrogen pressure introduced into of the powder feed hose.

The powder feeder provides reliable feeding of both coarse and very fine powders.

For example, WC-based powders as small as 1-10 microns are routinely used with this feeder when spraying with our compact hand-held or internal diameter gun using our static-dissipating powder hose.

The Powder Feeder Specifications:

| Feature | S.I. Units | U.S. Units |

|---|---|---|

| Power | 110 VAC/ 50-60 Hz/ 3 Amp – single phase 240 VAC/ 50-60 Hz/ 1.5 Amp – single phase | |

| Working pressure rating | 10 bar | 150 PSIG |

| Canister capacity | from 3.38L (standard) to 10.45L | from 206 Cu. In. (standard) to 615 Cu. In. |

| Wheel speed, RPM | 0.0- 32.0 | |

| Wheel speed accuracy, RPM | 0.1 | |

| Weight | 44 kg | 97 lbs. |

| Dimensions, L x W x H | 818 x 325 x 775 mm | 32.2” x 12.8” x 30.5” |

The Zimmer Fuel Vaporizer

Specifications:

Vaporizer type: dry electric; feed through.

Approvals: UL, CUL, CE, DEMKO, PED (SEP), ATEX.

| Feature | S.I. Units | U.S. Units |

|---|---|---|

| Vaporization capacity @ 240 VAC | 40 kg/hour | 88 lbs./hour |

| Power: | 100- 240 V AC/ 50-60 Hz 27.3 Amps @ 120 V AC 21.7 Amps @ 208 V AC 21.3 Amps @ 220 V AC 19.5 Amps @ 240 V AC |

|

| Heat exchanger: | ||

| Surface area | 1,200 cm2 | 186 in2 |

| Design pressure | 17.24 Bar | 250 PSIG |

| Proof pressure | 86.2 Bar | 1,250 PSIG |

| Relief valve set | 17.24 Bar | 250 PSIG |

| Overall dimensions, LxHxW | 791x 260.1×162.7 mm | 31.14×10.24×6.40 inch |

| Shipping weight | 30 kg | 66 lbs. |